White Paper: DuPont Non-Halogentated Flame Retardant Polymers for Electrical and Electronic Applications

Article

A white paper guide for design engineers and material specifiers

How to meet regulatory, environmental, safety and performance challenges in electrical and electronic components with DuPont NHFR polymers

NHFR Polymers from DuPont for Electrical and Electronic Applications

The electrical and electronic (E&E) industry is under unprecedented regulatory pressure to improve product safety and performance, and to reduce the health and environmental impact of the plastics and elastomers used.

Tough legislation requires these materials to be halogen-free and flame-retardant (NHFR), produce low smoke emissions, and comply with the WEEE (Waste Electrical and Electronic Equipment) Directive, the EU RoHS (Restriction of Hazardous Substances in Electrical and Electronic Equipment) Directive, and the EU REACH Regulation, requiring the industry to manage the risks from chemicals, and progressively substitute the most dangerous.

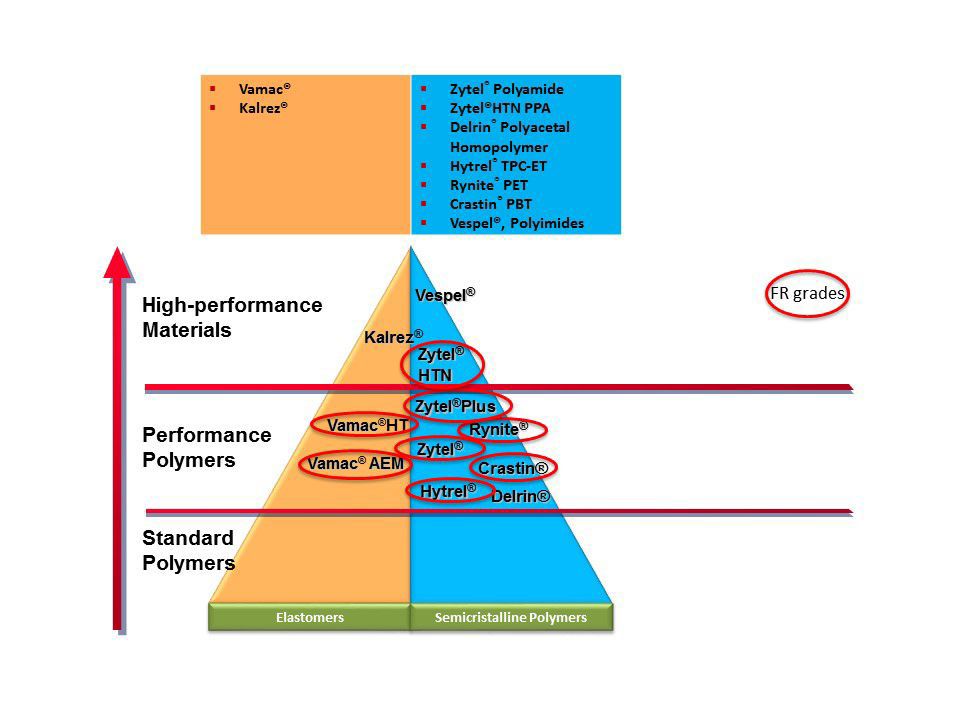

The solutions to many of the urgent E&E market needs are provided by DuPont— the largest portfolio of high-performance fully compliant NHFR products for electrical components including DuPont™ Crastin® PBT resin, DuPont™ Hytrel® TPE resin, DuPont™ Rynite® PET resin and DuPont™ Zytel® PPA and PA66 polyamides — backed by DuPont know-how in processing, predictive engineering and Computer Aided Design.

Components manufactured by the electrical and electronic (E&E) industry must meet unprecedented regulatory, environmental, safety and performance challenges. That means the materials used in the design and construction of every E&E part made today must meet tougher demands than ever before. Many plastics and elastomers traditionally used in products such as LED lighting, connector systems, circuit breakers and other electrical components are less able to meet all these requirements, either because they are not regulation-compliant, or do not satisfy the latest high performance needs, or both.

This white paper takes a step-by-step guide through the regulatory framework and environmental issues confronting the industry, looks at the key emerging trends, outlines DuPont’s materials and applications development expertise and helps engineers and specifiers select the DuPont products that will bring the greatest benefits to their application.

Table of contents

- The regulatory framework challenging the industry

- Environmental and safety issues facing the industry

- Key emerging trends in electrical and electronic markets

- DuPont: The industry’s widest portfolio of NHFR material solutions:

- Crastin® polybutylene terephthalate (PBT)

- Hytrel® thermoplastic polyester elastomer (TPC-ET)

- Rynite® polyethylene terephthalate (PET)

- Zytel® polyamide resins (PPA and PA66)

- Selecting DuPont materials by application

- How DuPont adds value to the industry