Mazda SKYACTIV-D diesel engine boosted by turbocharger parts

Case Study

Mazda SKYACTIV-D diesel engine boosted by turbocharger parts

Pressure to meet escalating fuel economy and emissions regulations drives auto manufacturers to develop new-generation engines that are lighter, cleaner, higher performing and more fuel efficient than ever before.

Mazda’s new 2.2-liter SKYACTIV-D diesel engine is an impressive example, achieving 20% better fuel efficiency than the engine it replaces, thanks to the lowest compression ratio of any mass produced diesel, while complying with global emissions regulations without the aid of expensive NOx aftertreatment.

The new engine, powering the Mazda CX-5 and the all-new Mazda6, has a new two-stage turbocharger that produces a smooth linear response and greatly increased low-and high-end torque right up to its 5200 rpm rev limit—key to exhilarating performance coupled with outstanding fuel economy.

But with turbocharger charged air temperatures reaching 200°C at pressures up to 200kPa in a wet, corrosive environment, some special materials were required to ensure lifetime durability for the turbocharges hose and air duct components. Those tough requirements led Mazda to specify DuPont™ Viton® fluoroelastomer and Vamac® ethylene acrylic elastomer for the hose and DuPont™ Zytel® HTN polyamide for the air ducts.

A plastic and rubber solution

“Mazda was looking for parts that would be durable under an extremely high temperature, high pressure and wet environment. But it was not possible to produce such pipes by injection molding without the technological expertise and support from DuPont, which we could not get from a part supplier. As a result, we chose DuPont as the only materials supplier that could provide both a plastic and rubber solution for this application,” said Takashi Yoshikawa, assistant manager, Powertrain Development Division, Mazda Motor Corporation.

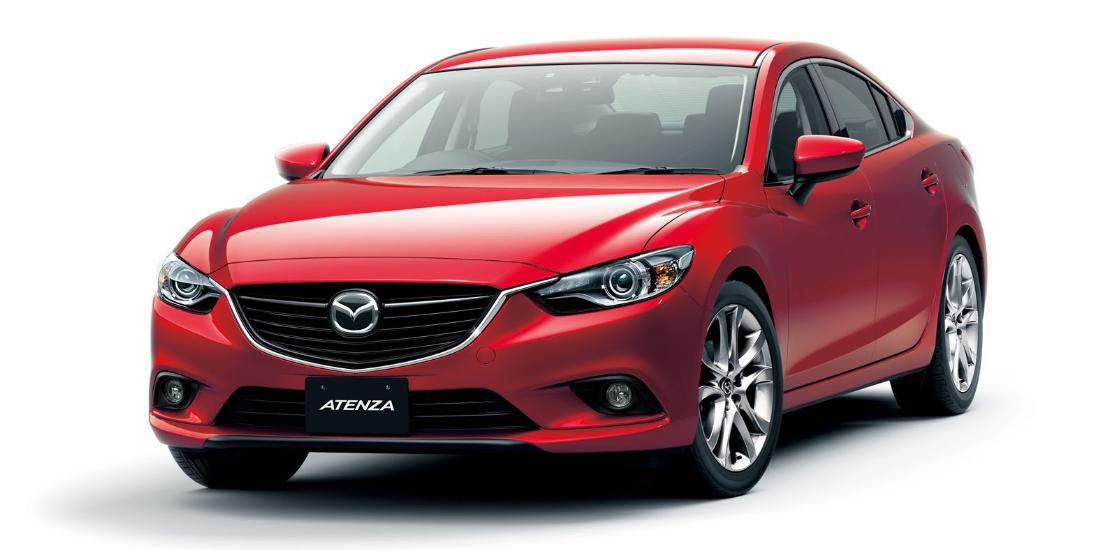

Mazda’s 2013 Mazda6 (Atenza in Japan), powered by the new turbocharged SKYACTIV-D diesel engine fitted with high performance turbocharger hoses and air ducts of DuPont™ Viton® fluoroelastomer, DuPont™ Vamac® ethylene acrylic elastomer, and DuPont™ Zytel® HTN polyamide

“Conventionally, alumite treatment was applied to aluminum castings. But this time a resin compound (PA6T-GF – Zytel® HTN polyamide) has been used, which results in reducing both unit price and weight, while meeting durability requirements under high temperature and pressure, and also corrosion resistance requirements. It is an advance over previous constructions,” Takashi Yoshikawa added.

Turbocharger hose construction

The turbocharger hose for Mazda’s new SKYACTIV-D diesel engine consists of an inner veneer of Viton® fluoroelastomer to ensure high permeation resistance to hot fluids and gases, intermediate and cover layers of Vamac® Ultra HT and GXF ethylene acrylic elastomer, and a reinforcing interlayer. The construction provides excellent mechanical strength, flexibility and vibration resistance coupled with the ability to withstand heat, chemicals and pressure, and provide an effective barrier to evaporative emissions.

Turbocharger air ducts of DuPont™ Zytel® HTN and hose of DuPont™ Viton® and DuPont™ Vamac® resist charged air temperatures reaching 200°C at pressures up to 200kPa and a wet, corrosive environment in Mazda’s new SKYACTIV-D diesel engine.

DuPont™ Viton® has been the elastomer of choice in seals and hoses for automotive fuel systems for nearly 50 years. It helps auto manufacturers meet tough LEV, PZEV and Euro 5/6 automotive evaporative emissions control legislation requirements by providing fuel system sealing capability for the lifetime of the vehicle, at operating temperatures well above 150°C or as low as -40°C.

DuPont™ Vamac® ethylene acrylic elastomers have been used successfully in turbocharger hose application since diesel engines were first equipped with turbo systems. In addition, the enhanced heat resistance and high flex capabilities of Vamac® Ultra HT mean even better dynamic flexing fatigue resistance for turbocharger hoses.

Air duct construction

A special 35% glass reinforced, heat stabilized grade of DuPont™ Zytel® high performance polyamide was used to produce the injection molded air ducts for the new two-stage turbocharger system for the Mazda SKYACTIV-D diesel engine—providing high heat, chemical, pressure, vibration and pulsation resistance.

DuPont™ Zytel® offers the industry’s broadest portfolio of nylon resins produced by the largest, most globally networked nylon manufacturer exclusively focused on the resins market. It includes Zytel® HTN PPA grades that retain stiffness, strength and mechanical properties despite exposure to high temperatures, long life coolant, chemicals and moisture.

Much more than a materials supplier

In successful commercial development programs such as this, DuPont acts as much more than a materials supplier by offering the services of a systems solution provider. Working in close collaboration with Mazda and two leading Tier 1 suppliers, DuPont provided not only material selection support, but also technical expertise in testing, processing, part design and assembly. This extended to molding and welding support including vibration welding performance, and to durability testing of candidate polymers for chemical, pulsation and fatigue resistance.